Bronze Bushing: The Relied On Element for Robust Mechanical Efficiency

Wiki Article

Everything You Need to Know About Bearing Bushings

From minimizing friction and use to providing stability and assistance, bearing bushings play a considerable duty in making sure smooth procedure and longevity of equipment. Recognizing the different kinds of birthing bushings, their importance, elements to think about when selecting them, as well as their setup and maintenance, can be overwhelming.Sorts Of Bearing Bushings

One of one of the most frequently utilized kinds of birthing bushings is the plain bearing bushing. This kind of bushing contains a cylindrical sleeve constructed from a low-friction product such as bronze or plastic. Ordinary bushings are simple in layout and offer efficient support and lubrication for revolving or sliding shafts.

An additional type of birthing bushing is the flanged bushing. bronze bushing. Flanged bushings have a flange or collar on one end, which helps to protect the bushing in position and stop axial activity. These bushings are typically used in applications where there is a requirement for added stability and assistance

Self-lubricating bushings are also commonly made use of in various markets. These bushings are constructed from materials such as bronze or graphite, which have self-lubricating buildings. This eliminates the requirement for exterior lubrication and decreases maintenance demands.

Additionally, there are round bearing bushings, which can suit misalignment and angular activity. These bushings have a spherical internal surface area that enables smooth rotation and motion in several instructions.

Importance of Bearing Bushings

Bearing bushings play a vital duty in ensuring the smooth operation and longevity of machinery and devices by supplying assistance, minimizing rubbing, and boosting stability between moving parts. These parts, typically made from metal or polymer materials, are inserted right into the housing or bore of a birthing to support and direct the rotating shaft or other moving parts.Among the key features of birthing bushings is to supply assistance. They assist distribute the tons uniformly, avoiding extreme anxiety on specific components and guaranteeing that the weight is effectively distributed. This support assists to protect against early wear and damage to the equipment.

In addition, bearing bushings boost security. They aid to maintain the positioning and positioning of the moving parts, avoiding any kind of undesirable activity or vibrations. This stability is vital for the correct functioning of the machinery and ensures the security of the drivers.

Variables to Take Into Consideration When Choosing Bearing Bushings

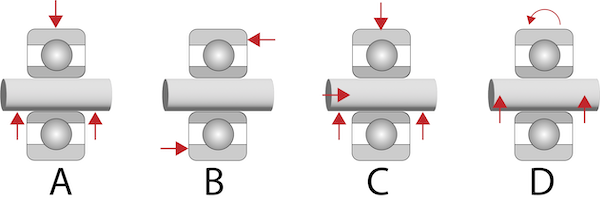

When selecting bearing bushings, it is vital to carefully consider various variables to make certain ideal efficiency and long life of the machinery or tools. Among the key factors to think about is the tons capability of the bearing bushing. It is vital to my blog pick a bushing that can take care of the anticipated tons without experiencing extreme wear or failure. The operating conditions need to additionally be considered. Aspects such as rate, temperature level, and lubrication requirements can affect the efficiency of the bushing. High-speed applications may need self-lubricating bushings to decrease rubbing and warm generation. Furthermore, the type of activity, such as straight or rotational, should be thought about when choosing a bearing bushing. Various sorts of bushings, such as sleeve, flanged, or drive, are available to accommodate details sorts of movement. One more important element is the compatibility of the bushing material with the breeding shaft or housing. The product ought to have excellent wear resistance, low rubbing coefficient, and compatibility with the lube utilized. The cost and accessibility of the bushing need to be considered to guarantee it fits within the task's budget and timeline. By carefully taking into consideration these aspects, one can make a notified decision and choose the most appropriate bearing bushing for their application.Installment and Maintenance of Bearing Bushings

helpful resources To guarantee optimal performance and prolong the life-span of bearing bushings, correct installment and routine upkeep are important. It is crucial to follow the manufacturer's recommendations and guidelines when it comes to installation. This consists of ensuring that the bearing bushings are effectively aligned and firmly fitted into the real estate or shaft. Incorrect installment can result in premature wear, boosted rubbing, and minimized effectiveness of the bearing bushings.Normal upkeep is vital for the smooth operation of birthing bushings. It is important to resolve any type of concerns quickly to protect against additional damage and potential failure of the bearing bushings. Proper lubrication assists to reduce friction, dissipate heat, and shield against deterioration.

Along with routine evaluations and lubrication, it is also recommended to periodically clean up the bearing bushings to remove any type of dirt, particles, or impurities that may have collected (bronze bushing). This can be done using a solvent or cleaner and a soft brush or cloth. It is necessary to stay clear of using severe chemicals or unpleasant products that could damage the bearing bushings

Typical Concerns and Repairing With Bearing Bushings

One of the most typical difficulties encountered with birthing bushings is appropriate positioning within the housing or shaft. When a bearing bushing is not lined up properly, it can cause excessive wear, increased rubbing, and early failure of the bearing bushing. To troubleshoot this problem, it is vital to first check the placement of the housing or shaft. Misalignment can happen because of incorrect installation, excessive lots, or thermal development. If imbalance is detected, it is essential to realign the housing or shaft to ensure proper performance of the bearing bushing.Another typical issue with birthing bushings is inadequate lubrication. Normal lubrication maintenance need to be brought out to ensure that the bearing bushing is appropriately lubed.

Furthermore, contamination can pose a significant concern for bearing bushings. In situation of contamination, the bearing bushing need to be completely cleansed and examined for additional hints any type of indicators of damage.

Final Thought

From decreasing rubbing and put on to providing stability and assistance, birthing bushings play a significant duty in making certain smooth operation and longevity of equipment.One of the most generally used kinds of bearing bushings is the plain bearing bushing (bronze bushing).One more kind of birthing bushing is the flanged bushing. Flanged bushings have a flange or collar on one end, which assists to secure the bushing in area and avoid axial motion. When a bearing bushing is not straightened appropriately, it can lead to too much wear, boosted friction, and premature failure of the bearing bushing

Report this wiki page